STONE EQUIPMENT

FOR SERIOUS FABRICATORS

TOTAL DIGITAL INTEGRATION OF THE STONE CUTTING PROCESS

MOST SOPHISTICATED STONE EQUIPMENT ANYWHERE

LDZ 2000 -

Fully-Automatic 5-Axis Bridge Saw

The LDZ 2000 Series represents the latest in 5-Axis Bridge Saw technology which can include automatic blade changing, blade calibration, precise mitering, coring and radius cutting. It’s the optimal machine for the most demanding requirements and tightly nested work pieces. Made especially for forward-thinking, small and medium sized companies, the LDZ 2000 is the ideal high-precision bridge saw that becomes a complete CNC work center when you add optional upgrades including:

• Laser Projection

• Vacuum Hold-Down System

• Automatic Tool Changer

• ISO 40 Tool Holders

• Under Slab Drilling and Rod Slotting

This combination provides a broad range of applications, from individual kitchen countertops, vanities, and shower pans to architectural products. In short, the flexibility, design and construction of the LDZ 5-axis bridge saw provides countless possibilities to meet your specific market demands.

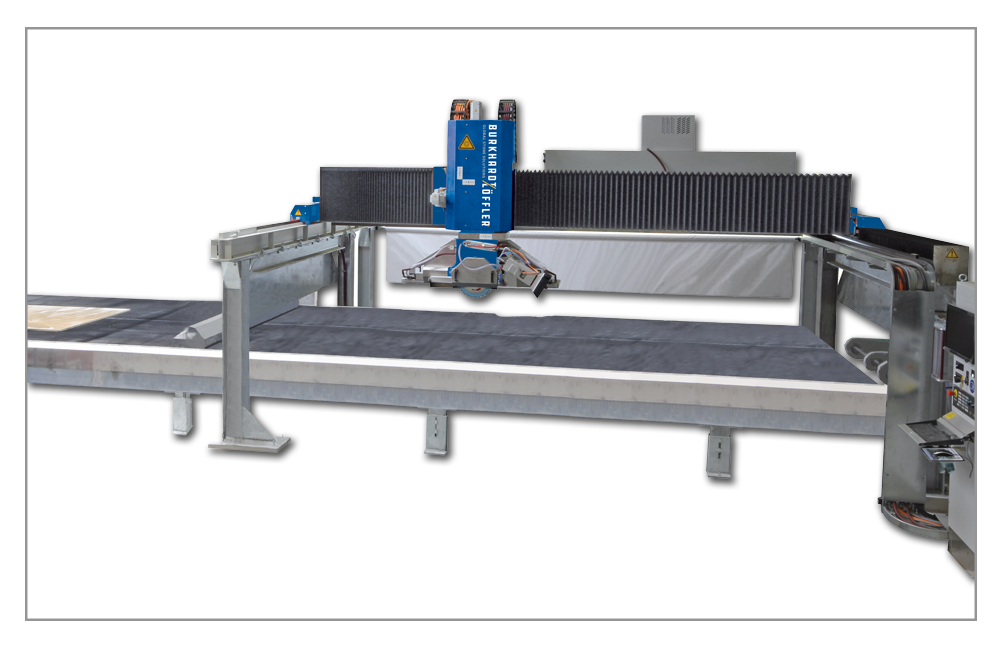

KSL 100/80 MG SERIES –

Granite & Quartz Edge Processor

No other stone processing equipment combines the experience and continuous technical development of the Burkhardt-Loffler KSL Series edge processors. Serious fabricators know the importance that comes from perfection in providing customers with a smart range of edge designs. The Burkhardt-Loffler modular design makes it possible to individualize the system to your market and production demands. Sophisticated features like:

• Planetary Polishing Heads

• Precise Miters

• Chamfer Profiling

• Pencil Edge Profiling

• Back Gauging

• Rod Slotting

This range of options and additions, can make your system a truly customized manufacturing asset. With over 2000 of these Burkhardt-Loffler precision edge finishing machines installed and operating worldwide, the KSL Series is designed to give you the edge on your competition.

CSA 598 -

Industrial Production 5-Axis Bridge Saw

With its slab autoloader, continuous belt table and automatic removal of finished work pieces, CSA 598 Bridge Saws deliver precision, reliability and economy. Burkhardt-Loffler modular design allows combining multiple 2D or 3D waterjet heads. Combining a waterjet bridge and saw bridge with vacuum work piece manipulation greatly increases kitchen countertop production.

Options Include:

• Single or Multiple Bridges

• Automatic Tool Changing

• Under Slab Drilling and Rod Slotting

• Automatic Work Piece Loading and Unloading

• Stationary Saw Table or Continuous Belt Table

• Digital Slab Imaging

• Slab Yield Optimization Software

The CSA 598 Series offers great choices for serious,

growth-oriented fabricators seeking to maximize production output.

WATERJET - 3D Cutting Machines

Waterjet cutting is the perfect solution for complex shapes and designs produced in granite, quartz, marble, porcelain, ceramic and glass. Precise miter cutting is enabled by the rotating swiveling head and the automatic surface sensors which compensate for differences in material thickness. Burkhardt-Loffler also engineered and manufactures a Waterjet 3D Twin-Table that allows loading and unloading of work pieces during continuous cutting operations, creating an efficient work flow. Add intricate inlay work for greater profitability with Waterjet 3D capability on your manufacturing line.